- 2024.02.10

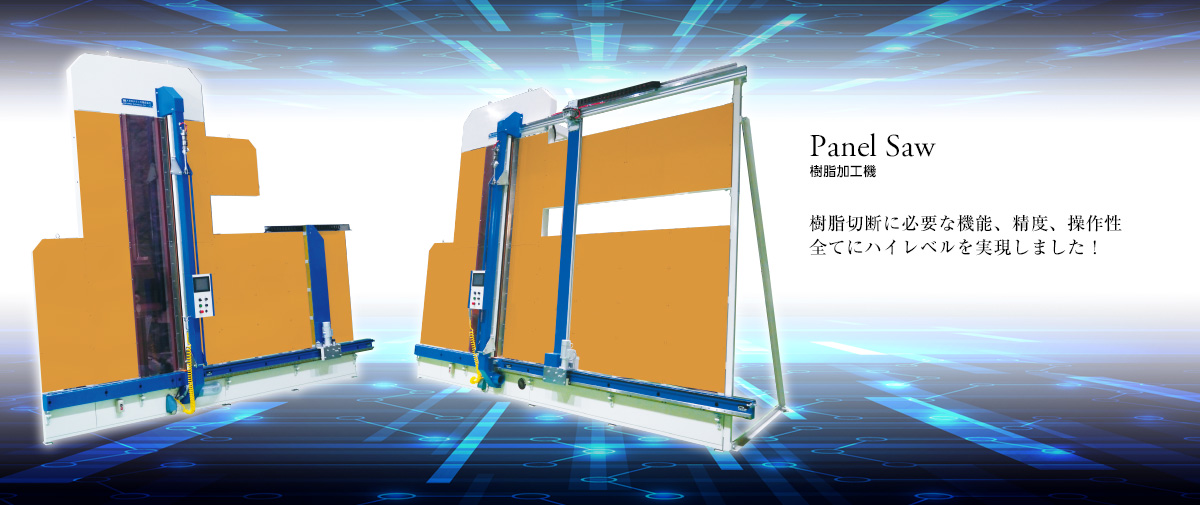

- 製品情報

- 2023.11.01

- 製品情報

- 2023.10.05

- 展示会

-

日本木工機械展2023に出展しました

- 2023.10.05

- 製品情報

-

新型切断機2機種を開発しました

-

偏光板加工機(異形・曲面加工)カンナ胴方式 PLPB-2518CP

-

偏光板加工機(異形・曲面加工)PLPB-180C・PLPB-3523CWA・PLPB-4523CWA

-

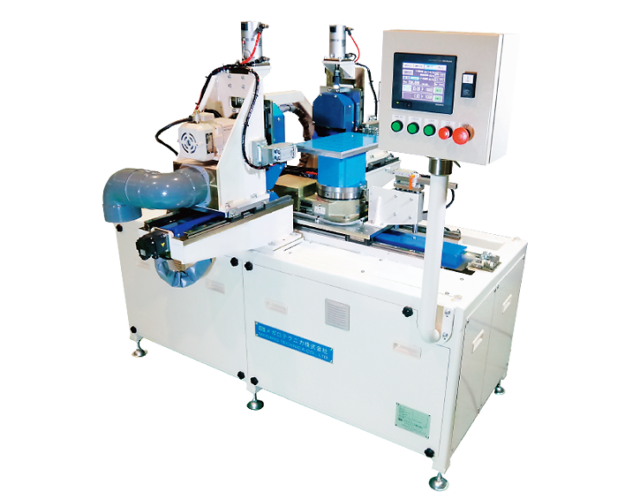

偏光板加工機(矩形加工 小型)PLPB-300

-

偏光板加工機(矩形加工 中型)PLPB-600・PLPB-850

-

偏光板加工機(矩形加工 大型・超大型)

PLPB-1350・PLPB-1450・PLPB-1850・PLPB-3100 -

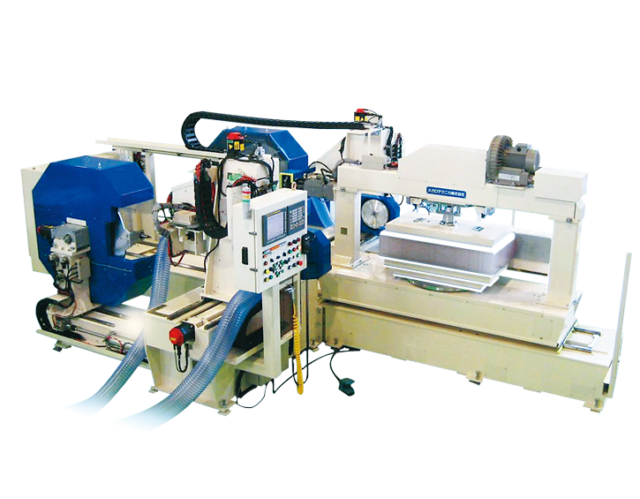

NC複合機(鏡面&溝加工) NCPB150F-2A・NCPB120F-2A・NCPB90F-2A・NCPB65F-2A

-

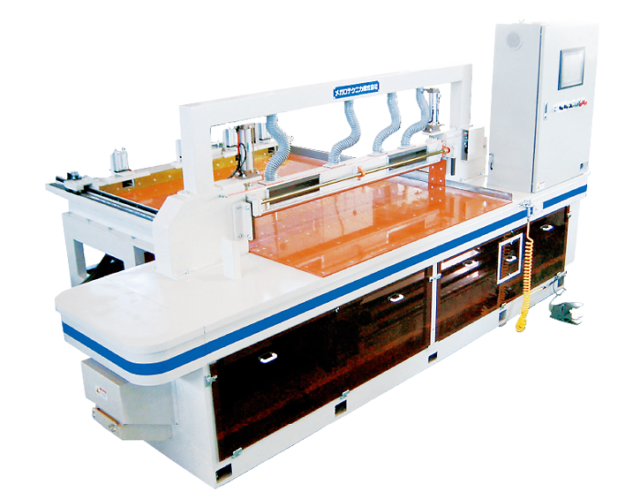

全自動プラビューティー MCPB-600A

-

ランニングプラビューティーPBR-1000・PBR-2000

-

4辺加工機 GCPB-R600

-

ランニングソー MRS-1500-D・MRS-2100-D・MRS-2400-D